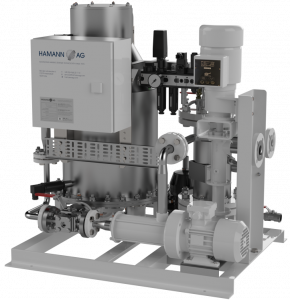

HL-CONT Plus Series

Sewage Treatment Plants – Performance and Versatility

HL-CONT PLUS marine sewage and wastewater treatment plants combine ultimate performance maximum versatility: Extensive customization options, complete dismantling and compact dimensions make these systems the all-rounders in our program.

Benefits of HL-CONT Plus Sewage and Wastewater Treatment Plants

Extensive Customization Options

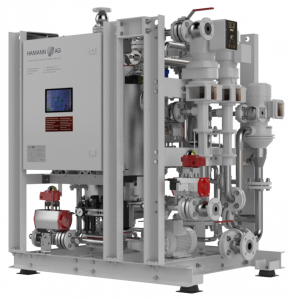

We offer a wide range of customization options for HL-CONT Plus wastewater treatment plants. This enables us to supply a system that exactly meets your specifications.

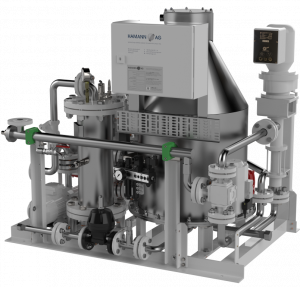

Simple Installation and Dismountable

With HL-CONT Plus systems, all components are integrated into one frame. which simplifies installation on board your vessel. All HL-CONT Plus sewage treatment plants can be completely dismantled. When dismantled, the largest components are small enough to fit through standard size hatches and doors.

Compact and Lightweight

HAMANN HL-CONT Plus sewage treatment plants are characterised by their small footprint and low weight. This makes them the perfect choice for applications where space requirements and weight are critical.

Specifications

Small & Light Sewage Treatment Plants

| Model | HL-CONT Plus 0125 | HL-CONT Plus 025 | HL-CONT Plus 05 | HL-CONT Plus 10 | HL-CONT Plus 20 | HL-CONT Plus 40 | HL-CONT Plus 80 |

|---|---|---|---|---|---|---|---|

| Capacity (liters/day) | 3.000 | 6.000 | 12.000 | 24.000 | 48.000 | 96.000 | 192.000 |

| Persons on board (180 l/day) | 16 | 33 | 66 | 133 | 266 | 533 | 1066 |

| Measurements w/d/h (cm) | 86/60/88 | 90/120/90 | 100/130/140 | 120/160/180 | 160/210/210 | 230/250/230 | 210/470/270 |

| Weight empty (kg) | 115 | 315 | 680 | 820 | 1450 | 1900 | 4700 |

| Electrical consumption (kW) | 2.1 | 2.3 | 2.6 | 3.5 | 5.2 | 8.5 | 15.0 |

| Vent connection (Inch) | 1/2 | 1 | 1 | 1 | 1 | 1 | 2 |

| Certification | All Models: IMO res. MEPC.227(64), EU MED Module B&D, USCG Type 2 (33 CFR 159) | ||||||

Proven Sewage Treatment Technology

Dissolved Air Flotation

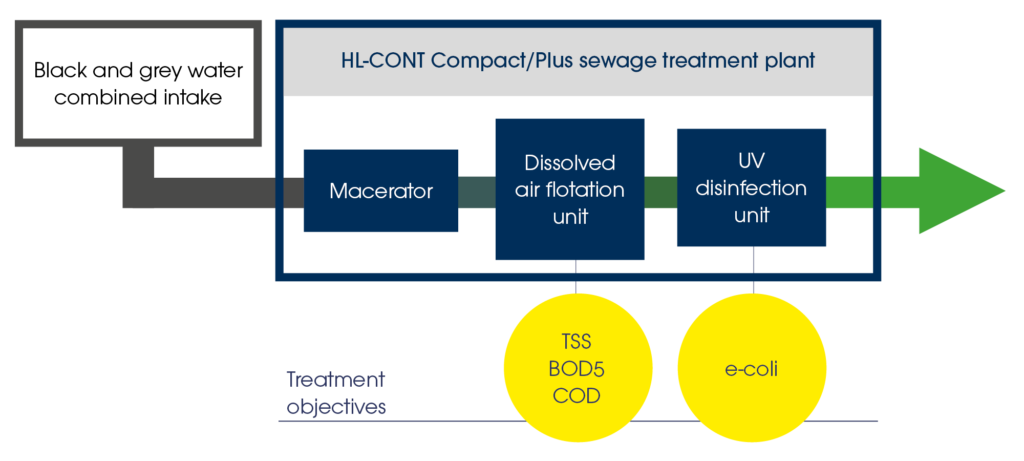

At the core of HAMANN HL-CONT Plus sewage treatment systems is our Dissolved Air Flotation (DAF) technology to separate the suspended solids (TSS) and to reduce the chemical (COD) and biological (BOD) oxygen demand. The principle of our DAF technology can be observed when opening a bottle of sparkling water: Pressurized water can hold gas that escapes rapidly when the pressure is released. In our system the macerated sewage is saturated with air under pressure. By suddenly releasing the pressure we create microbubbles that adhere to suspended solids in the sewage and float them to the top of the flotation tank. The accumulated sludge is skimmed and lead to a sludge tank. The final step of the treatment process in HL-CONT Plus sewage treatment plants is the deactivation of e-Coli microbes by UV radiation.

Uncompromising Quality

Top Quality Components and Materials

We use only the best components from reputable manufacturers and carefully select all materials to meet the requirements of operation in a maritime environment. HL-CONT Plus wastewater treatment plants are made entirely of metal; all parts in contact with the wastewater are made of stainless steel.

Designed and Manufactured in Germany

All our plants and systems are designed and manufactured in Hollenstedt, Germany according to our DNVGL-accredited ISO 9001 quality management system.

Proven Track Record in Marine Wastewater Treatment

HAMANN delivered its first sewage treatment plant back in 1972, even before the first IMO resolution on sewage treatment was adopted. Since then, we have installed over 5.500 sewage treatment systems on superyachts, ferries, cruise ships and naval vessels all over the world.

Unrivalled Performance in Wastewater Treatment

Ease of Operation

The routine functions are fully automatic, no special crew skills are required to operate a HL-CONT Plus wastewater treatment plant.

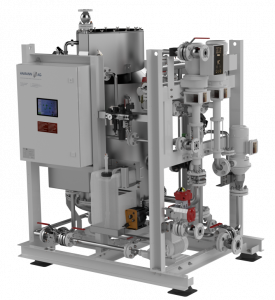

Ultimate Reliability

Proven technology and manufacturing to the highest quality standards combined with straightforward operation and low maintenance requirements give our wastewater treatment systems the reliability they are known for around the world.

No Membranes or Filters – Minimun Maintenance Requirements

There are no membranes or filters in HAMANN HL-CONT Plus sewage treatment plants, because they have to be cleaned, maintained and replaced regularly. All routine maintenance work can be carried out quickly and easily by the crew on board. The open design allows easy access to all components for inspection and service purposes.